Tue Apr 16 '19 Announcement

about 5 years ago

– Tue, Apr 16, 2019 at 03:42:23 PM

Dear Wynd Community,

We loved reading your positive comments on our last update, and we’re always grateful for how willing you are to share feedback (and encouragement!) with us. The team has been hard at work for the past few weeks and we wanted to provide the latest update on our progress!

Manufacturing Progress

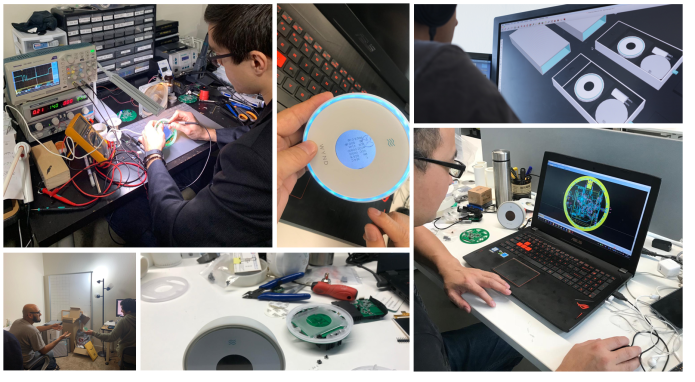

We’ve come a long way in the manufacturing process, including, finalizing product design and prototypes, initiating tooling and injection molding, sourcing components, and adding finishing touches to UX/UI on the app.

Wynd team hard at work

Wynd team hard at work

Wynd Home Purifier Progress

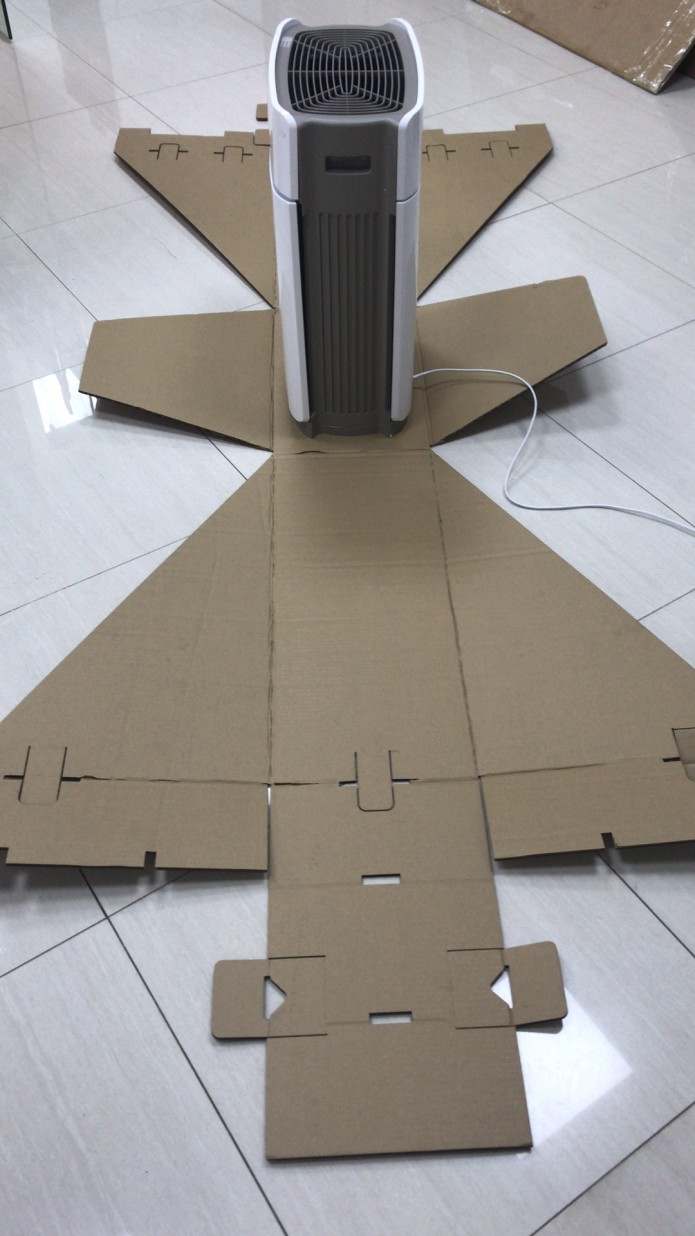

The Wynd Home Purifier is progressing well, we already made a trial run of 50 Wynd Home Purifiers and they’re pretty close to being finalized! There are only 2 items remaining - finalizing firmware (which enables some of the smart functionality) and the universal power port which allows the Purifier to be used around the world, regardless of voltage or plug type.

5 Wynd Home Purifiers!

5 Wynd Home Purifiers!

Wynd Halo

On the Wynd Halo, we had to make many engineering changes which we think will result in a more accurate, better looking, and better performing device. However, while we were expecting to start shipping in May, these changes will result in delaying overall shipments to August. We’re incredibly sorry about this delay, and wanted to explain why we think taking some extra time right now is necessary to ensure a better product experience for everyone.

Wynd Halo is designed to be the most sophisticated environmental sensor system that is incredibly easy to use and beautiful to look at. However, as part of the journey of getting to manufacturing, we faced a number of unforeseen engineering challenges that are now completely resolved. We thought it’d be educational to provide a detailed overview of the obstacles we’ve encountered and the design changes made to Halo. Specifically, we made the following major changes which improved the overall product but resulted in a delay to the timeline:

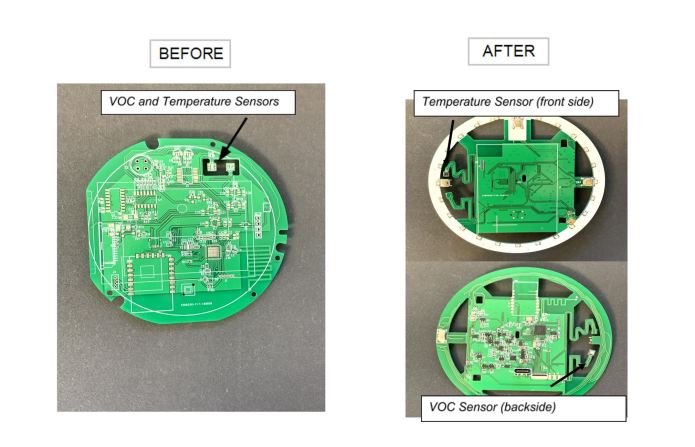

- PCBA (PC Board Assembly) change to optimize sensor placement and improve sensor accuracy.

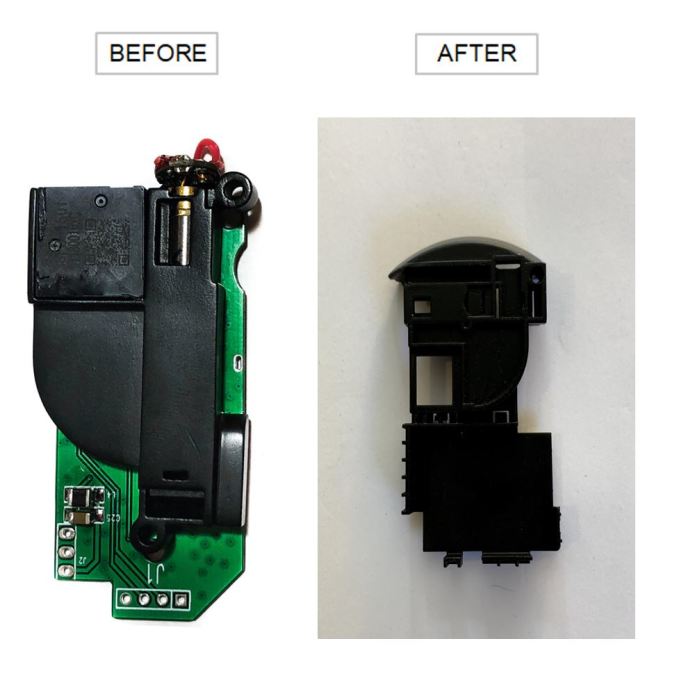

- Reconstructed air flow design inside the Halo enclosure to improve Air ID functionality.

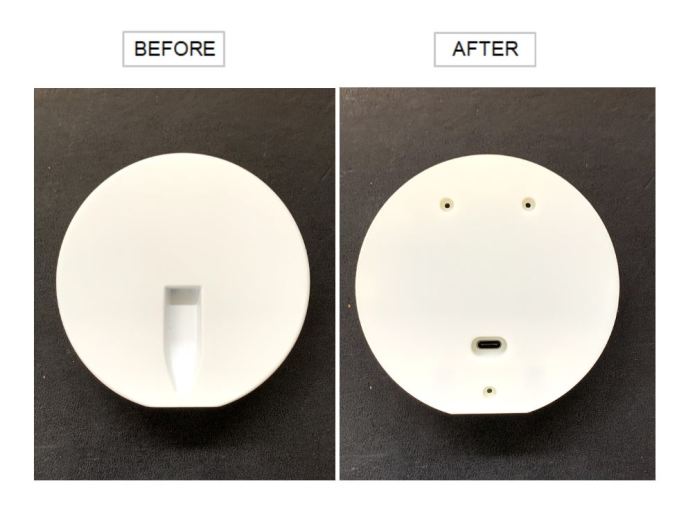

- Changed from micro-USB to USB-C.

- Switched from capacitive touch to physical buttons.

- Multiple tooling iterations.

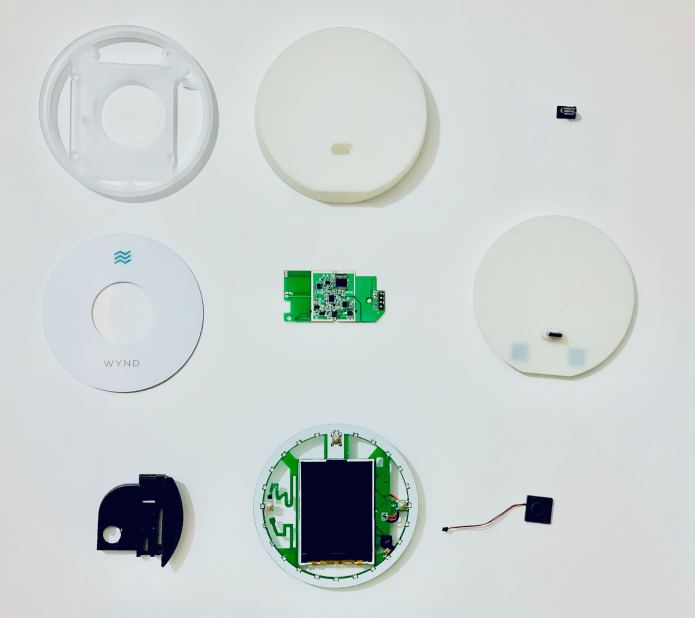

Large improvements with new PCBA including creating distance between VOC and temperature sensors, layout taking into consideration airflow mechanics, and sensor re-arrangement

There are 10 different sensors in the Wynd Halo, and while there’s plenty of space inside the enclosure we underestimated the challenges with interference from the sensors, specifically with heat dispersion. Our VOC sensor is accurate but emits heat (4°C increase to the board), which interfered with our temperature sensor. We ended up testing 10 different versions of sensor placement to thermally isolate the VOC sensor from the temperature sensor, and ultimately found a successful solution (as shown in the above picture of the PCBA).

Redesigned extended chassis housing the PM monitor and enabling better air flow inside the enclosure.

Wynd products have always featured a minimalist design aesthetic. In our original design, we had small openings (almost not visible) around the circumference of the Halo to allow air in and out, and three fans inside to move the air across the various sensors. However, this design proved to be loud and didn’t diffuse air properly. We had to redesign the internal PM module, and leverage its onboard fan to drive air flow. In parallel, we expanded the openings around the circumference. The result of these changes is a much quieter operation that allows air to flow across all the sensors, while preserving the design intention.

We changed from micro-USB to USB-C (left versus right picturer), and also simplified the plug so that it plugs in orthogonally to the device. The three holes you see on the right are for screws so that the Halo can be easily opened up in case of future upgrades and easy repairability, but don't worry the holes will be covered up by an overlay.

As many of you know, we originally were going to implement micro-USB to charge the Halo device, but based on community feedback we moved to a USB-C design. We agree it’s the right choice but had to change our mechanical design and the underlying PCBA to accommodate.

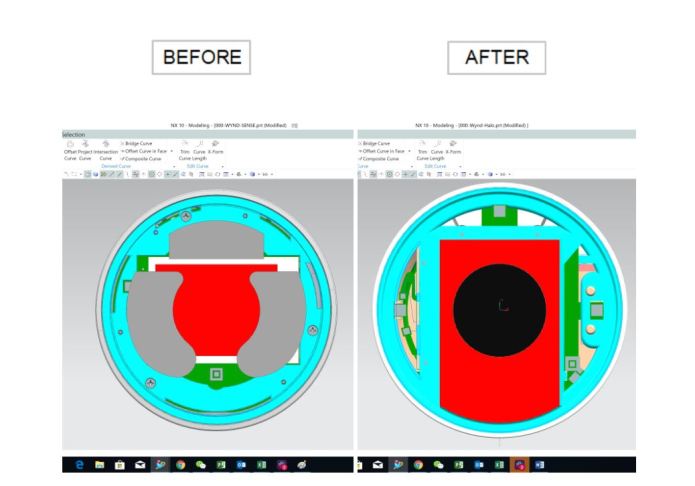

BEFORE - CAD of capacitive touch pads in grey AFTER - CAD of physical buttons indicated by grey squares

Our original design featured 3 capacitive touch pads (one on the top, left, and right side of the front face), and we had several working prototypes with this design. What we discovered as we were preparing for production is that getting the capacitive touch pads to work reliably and not interfere with each other (or the LCD screen) was difficult. Rather than risk having functionality issues at mass production, we decided to proactively change to physical buttons that are hidden under the front face of Halo. This mechanical and electronics change is a major one but we think necessary to ensure a positive product experience.

Tooling iterations. On the left image you can see the preliminary shape of the Halo backside, including the USB-C port. On the right image you can see the front-side which shows the spacing for the LCD screen. We've made more than a dozen changes to the tooling to get the molds right for final production.

Tooling iterations. On the left image you can see the preliminary shape of the Halo backside, including the USB-C port. On the right image you can see the front-side which shows the spacing for the LCD screen. We've made more than a dozen changes to the tooling to get the molds right for final production.

Tooling is the steel mold which is used to make plastic enclosures - in this case the outer shells of the Halo as well as the interior sensor module chassis. We needed to make a number of refinements of these tools in order to perfect the fit so that we can manufacture at high yields.

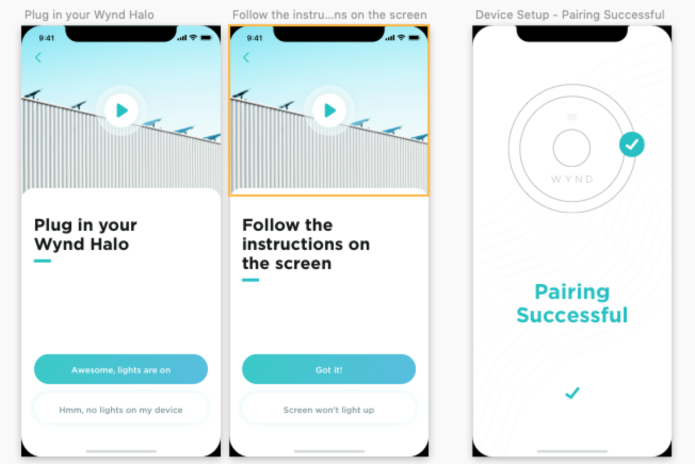

Software Updates

On the app side we’re excited to let you know we’ve developed multiple functionalities including Wynd “Quick Control,” This allows you to seamlessly control multiple devices within a few taps, without having to open different apps or go through multiple clicks to optimize your space. iOS / Android front-end, as well as backend development are well underway.

Next Key Milestones

- Tooling – April completion

- Firmware + Software Testing - May

- Certifications – May

- Engineer validation testing EVT - May

- Design validation testing DVT – June

- Product validation testing PVT - June

- Mass Production - July

- Product delivery – Shipment begins in August

Again, we’re incredibly sorry for the delay. Our teams have been working tirelessly around the clock to bring the product to life and made the difficult decision to take the extra time to ensure we deliver you the best possible product. There’s a lot of work ahead of us, but we are excited to continue towards our goal of providing you with quality products that you will love. As always, we will keep you all updated on our progress in a transparent way. If you have any questions or feedback, please email us at [email protected].

We couldn’t do anything without all of you. Thank you for your continued support of Wynd— our products, our team, and our vision.

Best,

the Wynd team